Clayton, great stuff here! I hadn’t see that mattress before but funny that design is really close to what I was envisioning I would need to do to make the air mattress base layer perform where I need it to (specifically to correct the alignment issue since I can obviously make the base very soft if I need to). Level’s use of soft, med and firm foams was almost exactly the experiment I tried on my floor with foams I had on hand (around 6" total thickness) and I could tell it did wonders for both pressure relief (esp on the shoulder) and alignment of the hips and lower back. The main difference I want to make sure I do with mine would be for me to have the ability to tailor the zones to fit my body proportions better and align them with exactly where I prefer to sleep on the bed.

Here’s the Level Bed mattress design:

.

.

[quote=“clayton” post=87378]

The weight distribution is a start, but really isn’t adequate since:

- Pressure is weight / area so you need to account for the amount of body contact in each zone

- Pressure is not evenly distributed within each zone due to the projection of various parts of the body

Both of these exacerbate pressure points, which have low area and high projection.

At the risk of stating the obvious, the key problem here is that beds are flat and people are not. We try to work around that issue using high elasticity covers and different ILDs of material. Obviously, the second problem is that few people sleep in only one position so we can’t fully optimize the bed for any one position – not to mention the issue of multiple sleepers with different needs.

I still think this is the right way to think about the problem. For the sake of argument, let’s assume we’re optimizing a bed for a side and back sleeper. We want the “profile” of that sleeper under those two conditions (in perfect alignment). This isn’t your profile when you’re standing, but under some reasonable level of pressure since some parts of our body are going to shift in response to the pressure of the bed while others (especially pressure points) are not. It’s even possible that we want less pressure on a pressure point that its “fair share”. The end product is two optimal profiles down the length of the bed in response to two specific pressure curves (higher pressure when side sleeping, lower pressure when back sleeping).[/quote]

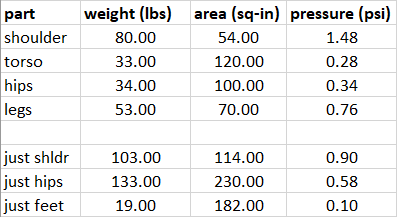

Again you’re right on with what I was thinking about how I would try to solve this. I thought about maybe doing some surface pressure modeling to see if that might help but that seemed overly complex for what I need to do here and I don’t have a complete materials database from which to draw on either. I thought about doing some of it by hand but quickly realized I really wasn’t interested in nasty integrals to figure out the exact surface area. So trying to simplify it as best I can I started thinking I might be able to just approximate the area making contact in each zone by creating rectangular approximations but I’m not sure how close this will approximate real world deflection of the mattress. I think this zoning will actually work pretty well for every sleeping position even stomach because it should support the hips well but we’ll have to see how that pans out. As you alluded to what I want to do is to provide more support to the hips/ribcage which should take pressure off the shoulder area. If you look at the weight distribution on someone my size (250lbs) the shoulder area can push down with over 80lbs of force which is alot on a relatively small area so no wonder people end up with shoulder issues from stiff mattresses. I hope this design will address it well.

.

.

[quote=“clayton” post=87378]

In theory (if not practice), we should be able to match each point down that chart with a material that has the right behavior. Your charts for ILD30 Dunlop and ILD22 Talay demonstrate how this optimization is possible. In some places (like pressure points), you’ll need the deflection to change significantly with added weight (and the Talay does this). The deflection compensates for the projection without adding too much pressure. In other places, you want the deflection to change very little so they bear more of the weight on the higher-pressure side position.[/quote]

You nailed exactly what my goal was with the materials charts and how I wanted to try and solve this issue. The problem I’m running into now is whether I have enough adjustability if I use a single 3" layer of foam to tailor the stiffness (like what Flobeds use on theirs) or if I need to move to using two 2" layers (so 4" total) to give myself more room and granularity to make the adjustments needed to bring my hips and center section into alignment. Unlike the Level mattress I don’t really want to cut and glue the top foam together so I’d prefer design-wise to keep the top layer in a single piece (primarily just pressure relief). In the zoned layer(s) I’m planning on trying both dunlop and talalay since they have different response characteristics depending on how much deflection I need to keep alignment correct.

This should be the approximate dimensions and weights in each zone on the mattress:

So my question is whether you think I’ll have enough depth to tune for alignment with a single 3" layer or do you think I’ll likely need 4" (two 2" layers) in order to achieve what I’m looking for? My plan was to use a 3" comfort layer of soft talalay on top of that to provide good pressure relief.